Business insight is the key to successful ERP cooperation

Atea FinlandIT infrastructure solutions provider Atea started using Microsoft Dynamics Business Central to serve customers more efficiently

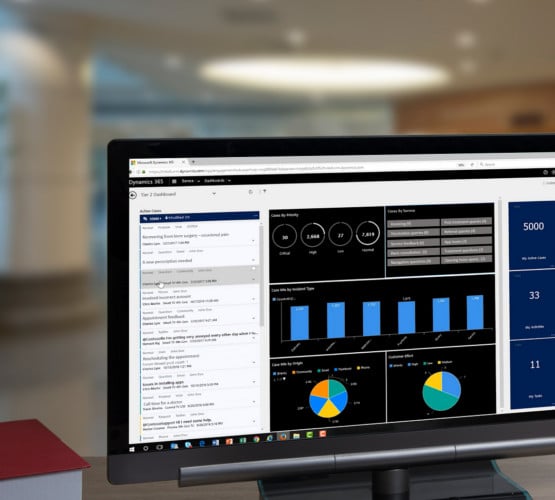

Read MoreTake control of your digital transformation journey with Microsoft Dynamics 365

Do you want to start your transformation at small scale, grow as business needs arise whilst only paying for what you need? We offer you intelligent business apps built on a market leading cloud platform to support your organization's transformation journey.

With Dynamics 365, you can activate business apps according to your organizations needs and ambitions. Take the capabilities of your existing solutions to the next level by connecting them with Dynamics 365 applications.

Empower your business and operational model of people and business processes to be connected and help drive productivity and collaboration levels beyond expectations. Dynamics 365 provides your organization with powerful flexibility and limitless possibilities.

At the core of transformation lies data and the ability to measure as means to optimize business. Dynamics 365 allows you to break down data silos and increase cross-departmental productivity, developing a 360-degree view of your business.

Natively working in the Microsoft Cloud, Dynamics 365 provides a scalable and secure business platform, where information can be easily stored, managed, and shared.

To us it's no longer about CRM and ERP projects. With Microsoft Dynamics 365, it's about putting your organization's key stakeholders and digital vision first and focusing on realizing business results over time and with pace together.

If you're looking to evaluate or improve your existing Dynamics and Microsoft cloud solution investment, don't hesitate to reach out.